Vibro replacement – Sustainable solution for ground improvement in soft clays

The master thesis aims to investigate effect of vibro replacement on Norwegian clays based on a full-scale test site and numerical simulations.

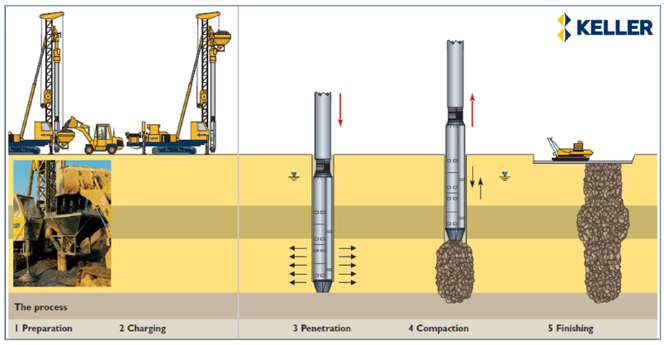

Vibro replacement is globally a widely adopted ground improvement method. This technique uses a bottom feed vibrator, penetrating fine soil (clay, silt and fine to medium sands) and filling the created space with crushed rock or gravel densified by the vibrator.

As a result, a so-called stone column remains in the ground. The stone columns will be stronger, stiffer and more permeable than the surrounding soil, thus, improving the soil behaviour regarding bearing capacity, settlement response and drainage.

In Norway, vibro replacement has, so far, received scant attention, likely due to very challenging ground conditions such as soft and sensitive clays (i.e., quick clay). Today, it is still uncertain if vibro replacement can be reliably performed in very soft clays and result in the required improvement.

The latest research indicated that vibro replacement is a more sustainable ground improvement method than deep soil mixing and bored, cast in-situ piles and can be increased by utilizing recycled aggregates as stone column fillers.

The research project VIBro rEplacement (VIBE)

The project VIBE, initiated by Keller Geotteknikk in cooperation with the Norwegian Geotechnical Institute (NGI), investigates if vibro replacement with recycled raw material is a suitable ground stabilisation solution in Norwegian clays by

- executing a full-scale test site at Onsøy (installation and loading of vibro stone columns, considering an extensive monitoring set-up)

- validating design guidelines using data from the test site and numerical simulations and

- assessing the environmental impact of vibro replacement with secondary aggregates.

The master's student investigates the possibilities and limitations of vibro replacements in soft soils in strong collaboration with the Norwegian Geotechnical Institute (NGI).

The Master's student examines the possibilities and limitations of gravel piles in soft masses in close collaboration with NGI.

The assignment

- Literature review on the vibro replacement, mainly focusing on (i) installation, (ii) monitoring, (iii) quality control and (iiii) numerical modelling of vibro-stone columns

- Visit the test site at Onsøy during the execution of cone penetration tests and the monitoring (e.g. inclinometer, piezometer, settlement measurements)

- Interpretation of monitoring data and in-situ tests: (i) development of excess pore pressures in soft clays due to the installation of vibro stone columns; (ii) comparison of CPTu results executed before and after vibro-stone column installation; (iii) interpretation and visualization of settlements due to the installation of vibro-stone columns and subsequent loading due to an embankment

- Numerical back-calculation of the test site based on a 3D model using the software package Plaxis 3D: (i) definition of model parameters; (ii) evaluation of settlements and comparison with monitoring data; (iii) sensitivity study, mainly focusing on the stiffness parameters of clay and vibro-stone columns

Simon Oberhollenzer

Project Engineer I Onshore Foundations simon.oberhollenzer@ngi.no+47 922 93 177