One of the greatest barriers to achieving a circular economy is the management of hazardous substances. The United Nations Sustainable Development Goal (SDG) 12.4 emphasizes the need for sound management of wastes and chemicals through their life cycles by 2020.

This issue especially comes to the fore with two types of wastes: sewage sludge and e-waste plastic. These hold tremendous circular potential for nutrient recycling, green energy and as a replacement source of raw materials. This potential, however, is not realized due to elevated levels of hazardous substances. Using raw sewage sludge as fertilizer is problematic due to exposure through food and water ways affected by agricultural run-off; recycling e-waste plastic is problematic due to recycling hazardous substances and environmental emissions during recycling.

SLUDGEFFECT will explore this in the context of addressing United Nation's Sustainability Development Goal (SDG) 12, in combination to synergies and trade-offs to other SDGs. By combining state-of-the-art knowledge and analysis of the presence of contaminants in sewage sludge fertilizers and e-waste plastic, with the literature and novel experimentation on how to remove hazardous substances through pyrolysis at high temperature (>700 C), the aim is to provide more than a proof-of-concept that hazardous substances risks can be mitigated through high temperature pyrolysis in Norwegian waste streams while making useful raw materials.

We will investigate how to integrate this risk mitigation within a circular economy and SDG analysis, how to optimize this process to achieve a better environment footprint, and further, how to advance such technology to develop products in the current regulatory and market situation within Norway. This novel research will be conducted in close collaboration with a user group from the national, regional and industrial sectors, grounding it firmly within the Norwegian regulatory and economic context.

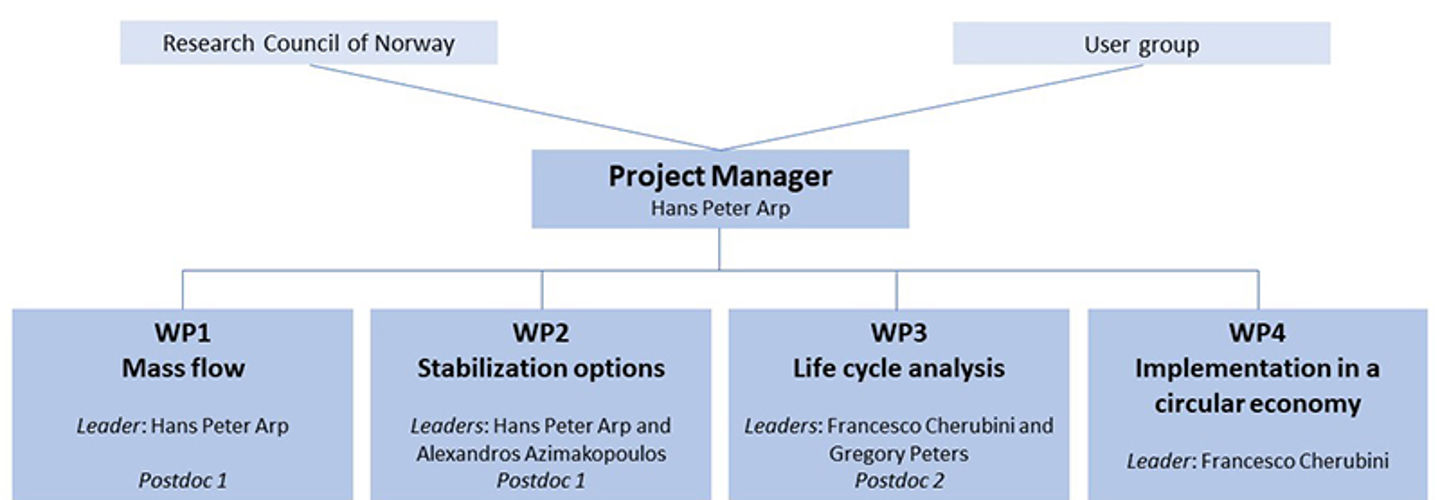

Project organization

The project will be carried out by an interdisciplinary team of researchers from Norway (NGI, NTNU), Sweden (Chalmers University) and Spain (IDAEA-CSIC), employ two postdocs, and have a user group from the National level (Norwegian Food Safety Authority & Norwegian Environment Agency); relevant Industry sector (Lindum AS, Scanship AS, Norsirk), and Regional actors (VEAS IKS, Trondheim Kommune). This will firmly anchor the state-of-the-art research, applications and implications within the Norwegian regulatory and market context.

More information on this is found under Project management (see the menu line above).

Work packages (WP)

Primary Objective of SLUDGEFFECT: Identify how thermal treatments can be optimized for removing hazardous substances in sludge and e-waste plastic for increasing recycling and sustainability

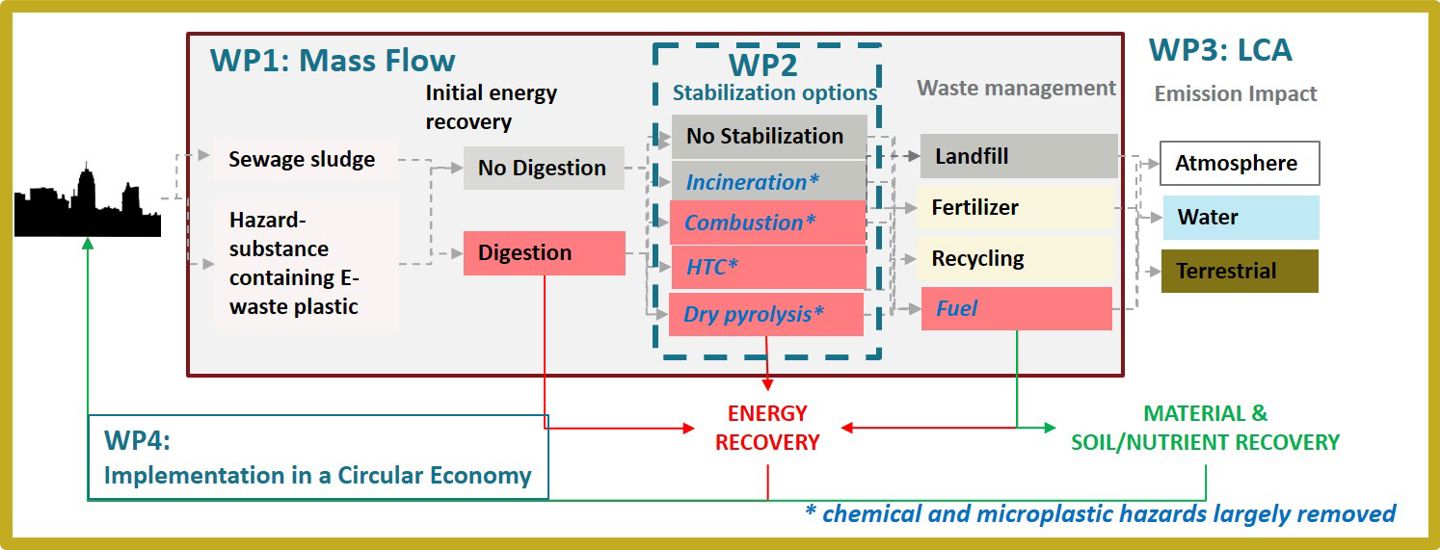

In order to achieve the primary objective of SLUDGEFFECT - Identify how thermal treatments can be optimized for removing hazardous substances in sludge and e-waste plastic for increasing recycling and sustainability, the project has been divided into four work packages (WP) with the following aims:

WP1 – Mass flow

Establish a mass flow of selected hazardous substances in sludge and e-waste plastic in Norway, considering environmental emissions from the status quo.

WP2 – Carbonization

Quantify how incineration, dry pyrolysis and HTC can remove selected hazardous substances from sludge and plastic; and characterize the hazards and innovation potential of resulting residues for reducing contaminant emissions.

WP3 – Life Cycle and SDG analysis

Establish a consistent framework for advanced environmental sustainability analysis of the waste treatment options using up-to-date life-cycle assessment approaches interpreted under a SDG context.

WP4 – Implementation in a circular economy

Integrate results with user feedback and regulatory considerations for innovation and societal recommendations.

Description of the different WPs are provided under Sub-projects (see the menu line above).